FORMULA® R Test System

The FORMULA® R Test System is an automated test and measuring system designed for comprehensive automated verification of the low-current DC electromagnetic relays with up to 8 coils and up to 12 contact groups.

The applications of the Test System are quality control of all stages of the relay lifecycle, including:

- testing and research of newly developed relay types in diagnostic modes

- Modes close to real conditions of relay operation in productsfactory acceptance and in-production testing in serial production: qualification, periodic, approval and stress testing

- certification testing

- analysis of deviations and failure prediction

- incoming inspection

The FORMULA® R meets the requirements of the metrological standards for measurements and tests in microelectronics.

Developer and the manufacturer of the Test Systems:

FORM, Russia

FORMULA® R Test System performs a comprehensive diagnostic control and measurement parameters of the relay in full accordance with MIL-PRF-39016F.

Basic technical characteristics and functional capabilities

The FORMULA® R Test System have been created to provide highly reliable measurements of the parameters of relays.

The key technical characteristics of the Test Systems are defined by the following values:

The Test System is a functionally complete automated tool for measuring a wide range of low-current relays, and provides users with the following advantages:

- High readiness of equipment for measurements and tests

- Automation of all stages of the measurement process and data management

- User-friendly, fully functional software

- Automatic diagnostics and metrological calibration

- Reliability in round-the-clock operations and availability of two workstations

- Ability to work with autoloaders

Wide range of application and continuity

The concept implemented in the FORMULA® R relay Test System provides its effective application in three areas:

- as measuring tools when testing relays in full accordance with MILPRF-39016F

- as a tool for analyzing the causes and mechanisms of relay failures during production

- as a means of predicting the reliability of the relay on tests and the incoming inspection of relay

Technical advantages

The fundamental innovations that are implemented in the Test System, provide the Consumer with the advantages of technical and metrological level, allowing:

- Relay timing parameters

- Contact resistance (resistance of the contact circuit at their closure)

- Pick-up and drop-out voltage/current using step voltage/current change program function

- dielectric withstanding voltage measurements at a voltage up to 800 V (1000 V)

- contact stabilization time and coil EMF measurements

- Identify the latent fault of the relay using a built-in high-resolution oscilloscope and software for testing and research of relays

- Perform failure analysis and prediction of relay reliability using arbitrary cyclograms

- Monitor the electrical parameters of resistor array (customized)

- Measure reed switch with low resistance contacts, short triggering and releasing times and high insulation resistance–up to 10 GΩ

Workplace ergonomics and safety

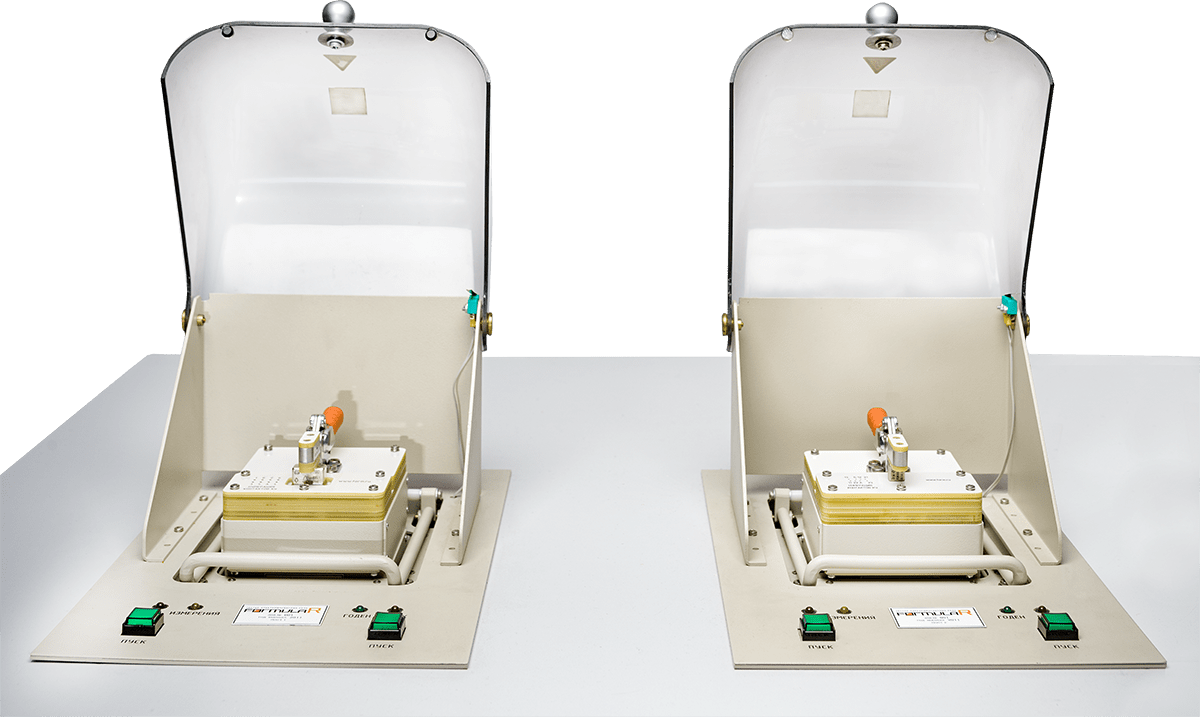

The Test System test head and the measuring stations for device under test connection are built in a special worktable supplied with the Test System.

The possibility of monitoring electromagnetic relays is provided at one or two measuring stations, with independent monitoring of two different types of relays.

Fig. 1

As a matter of convenience, the start buttons on the operator panel are placed under the right and left hand.

In manual measurement mode, operators only work with the «Start» button and display panel that show the «Accept» and «Reject» results.

All testing results are automatically saved in the database of the Test system, as well as in the cloud data base Kamchatka®

The design ensures reliable protection of the high-voltage measurement zone, guaranteeing complete electrical safety for the operator.

For maximum performance and safety, the Test system has a fully automatic measurement mode using autoloaders and environmental chambers.

The test system’s maintainability is provided by its modular design and automated diagnostic tools, both autonomously and via the Internet, to identify test system faulty unit. Diagnostic system and test system design allow to repair the test system in case of failure within 1 day in field.

FORMULA® R Test system software

FORMULA® R Test System operation is highly automated and controlled by FR software developed by FORM for maximum user convenience

Test fixture.

TestBox® Test Solutions

The FORMULA® R Test System delivery package includes diverse types of measurement accessories developed and manufactured by FORM to ensure that the system is introduced into the user’s operations as quickly as possible and provide a faster return on investment.

The Delivery set of the Test System includes complete instructions and documentation for self-development of test fixture for connecting the relay.

So that FORMULA® R Test System clients can more quickly achieve their business objectives and promptly see a return on investment, FORM offers both factory-ready and custom TestBox® Test Solutions for measuring specific types of relay.

Each TestBox® Test Solution includes:

- specialized test fixture for connecting a specific type of relay

- a disk with relay test program

- a datasheet with TestBox® operating manual

- manufacturer’s warranty

The quality of the TestBox® Test Solutions is defined by their compliance with the electronic component base regulations, the technical requirements and the Customer’s specifications. The TestBox® test solutions are supplied as part of the Test System delivery set, or individually, any time throughout the life cycle of the equipment.

Today, more than 550 types of Test Solutions already developed are used by the FORMULA® Test System Clients, providing consistent metrological support for quality control of electronic components.

By purchasing the TestBox®, Clients can significantly reduce the time required to put their products on the market.

TESTBOX®Means for integration with external equipment and IT systems

On customer request we can develop and build a custom workplace solution, with external equipment integration if needed.

To meet traceability requirements, workplaces based on the FORMULA® Test System are connected to the Kamchatka® information database.

Manufacturer’s services

To reduce the Client’s time and costs for support work, FORM offers the following technical services to FORMULA® R Test System Clients:

- Integration of FORMULA® R Test Systems into the Client’s technological, informational and testing infrastructure, with connection of external equipment, instruments and IT networks

- Scheduled maintenance, repair and metrological services at the place where the ATE is operated

- Development of non-standard methods of testing on the Customer’s terms of reference

- Expansion of the ATE configuration according to a list of typical options, or with custom development of options

- Design of specialized test fixture or TestBox® test solutions for measurements and tests of relay

- Technical support of the Consumer at the claim settlement