FORMULA® TT2 Test System

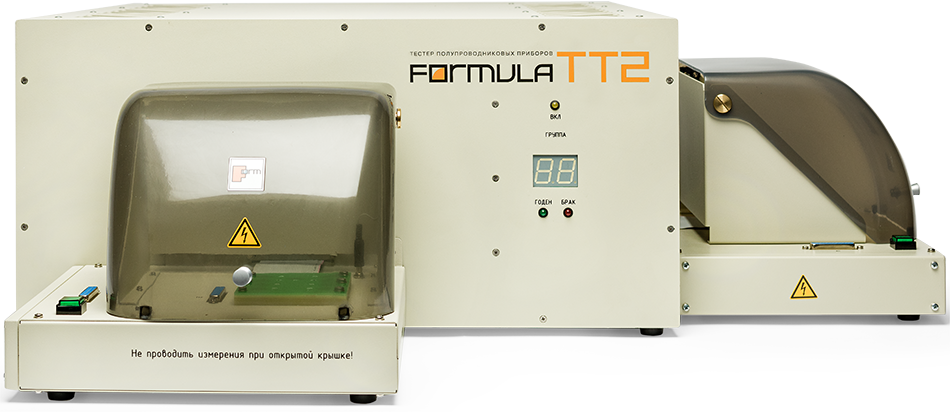

The FORMULA® TT2 Test System is a universal testing and measuring system designed for comprehensive automated verification of the static parameters of semiconductor devices: field effect and bipolar transistors, diodes, thyristors, voltage regulator diodes, optrons and microassemblies.

The applications of the Test System are quality control of semiconductor devices when conducting tests and studies of newly developed types of semiconductor devices, and during inproduction testing in series production.

The FORMULA® TT2 meets the requirements of the metrological standards for measurements and tests in microelectronics.

Basic technical characteristics and functional capabilities

FORMULA® TT2 Test Systems have been created to carry out highly reliable measurements of the parameters of semiconductor devices. The key technical characteristics of the Test Systems are defined by the following values:

In manual measurement mode, operators only work with the “Start” button and display panels that show the “Accept” and “Reject” results, with the option to sort devices tested by various suitability groups. After each measurement, the display shows the number of the suitability group, using up to 69 types of grading.

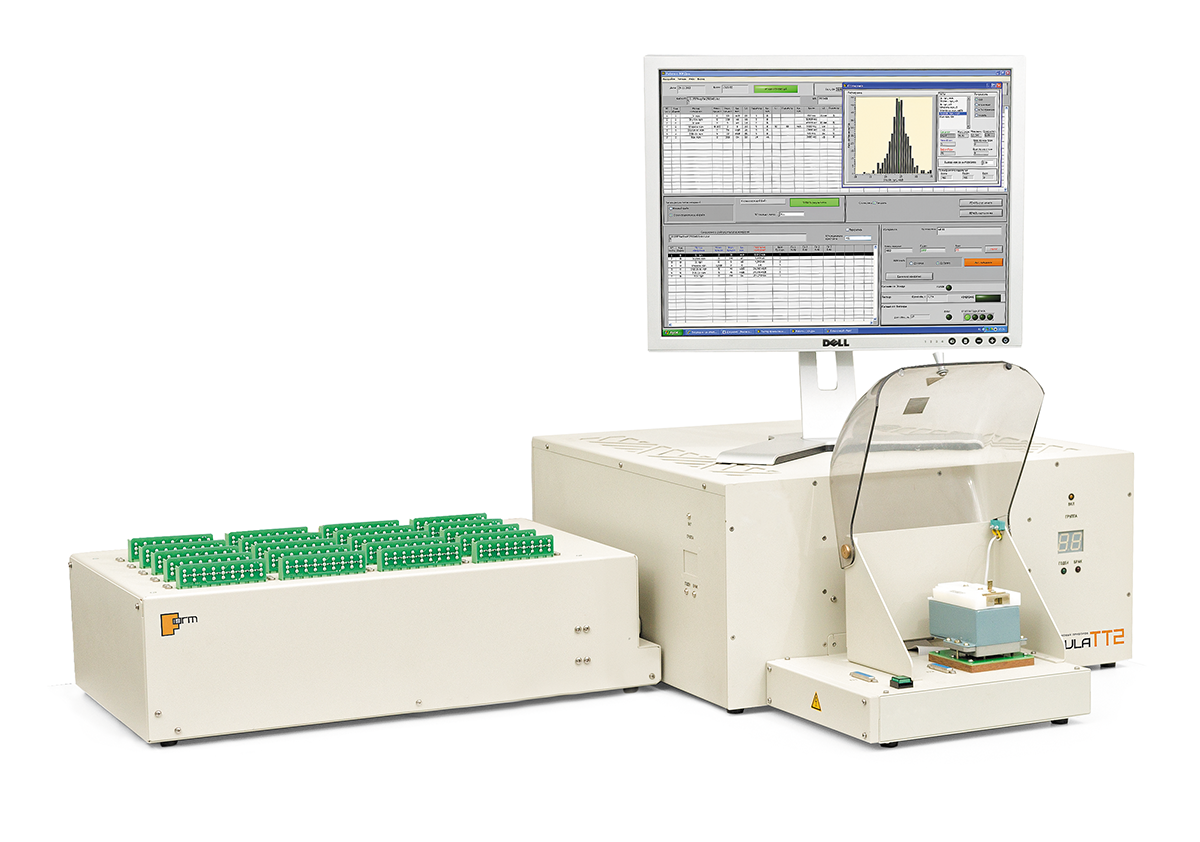

Means for integration with external equipment

The FORMULA® TT2 Test System is equipped with hardware and software for integration with external equipment: probes, test equipment, external devices, handler.

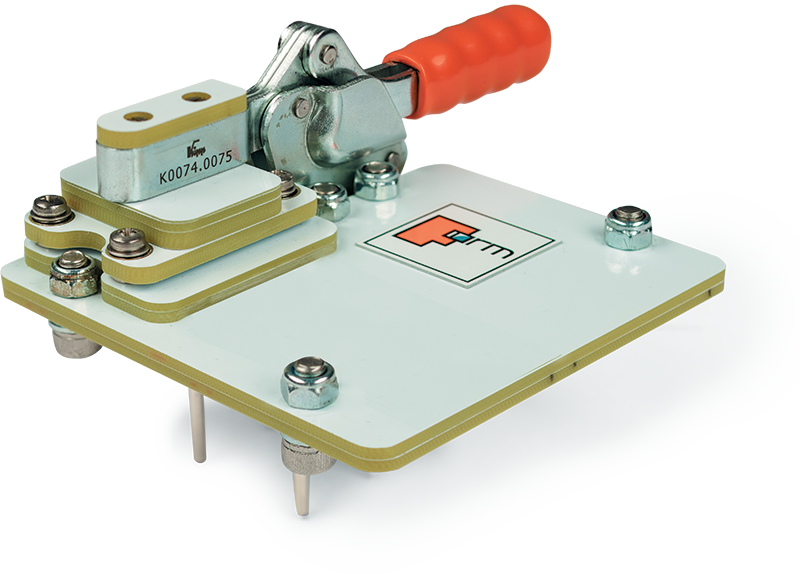

Measurement accessories

The FORMULA® TT2 Test System delivery package includes diverse types of measurement accessories developed and manufactured by FORM to ensure that the system is introduced into the user’s operations as quickly as possible and provide a faster return on investment Fig. 8.

Custom and factory-ready TestBox® Test Solutions

So that FORMULA® TT2 Test System clients can more quickly achieve their business objectives and promptly see a return on investment, FORM offers both factory-ready and custom TestBox® Test Solutions for measuring specific types of microcircuits: under normal conditions and under the impact of extreme temperatures.

A group of experienced engineers at our testing laboratory develops designs and software for Test Solutions. The quality of TestBox® Test Solutions is the result of their correspondence to the regulations on electronic components, technical requirements and Client specifications.

test solutionsManufacturer’s services

To reduce the Client’s time and costs for support work, FORM offers the following technical services:

- Integration of FORMULA® TT2 Test Systems into the Client’s technological, informational and testing infrastructure, with connection of external equipment, instruments and IT networks

- Scheduled maintenance, repair and metrological services at the place where the ATE is operated

- Organization of workstations based on FORMULA®TT2 Test Systems with a database for ensuring traceability of measurements

- Expansion of the ATE configuration according to a list of typical options, or with custom development of options

.webp)