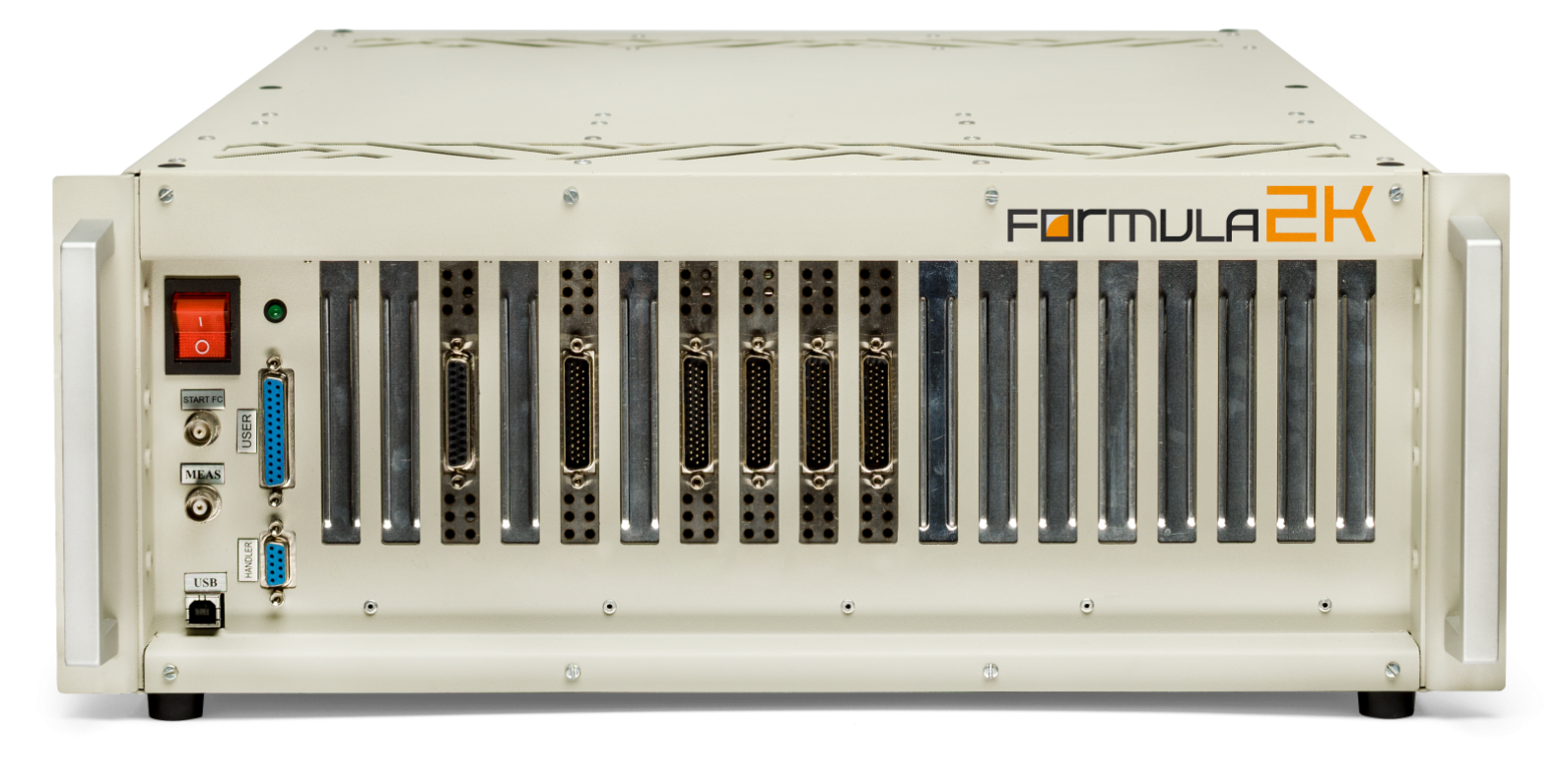

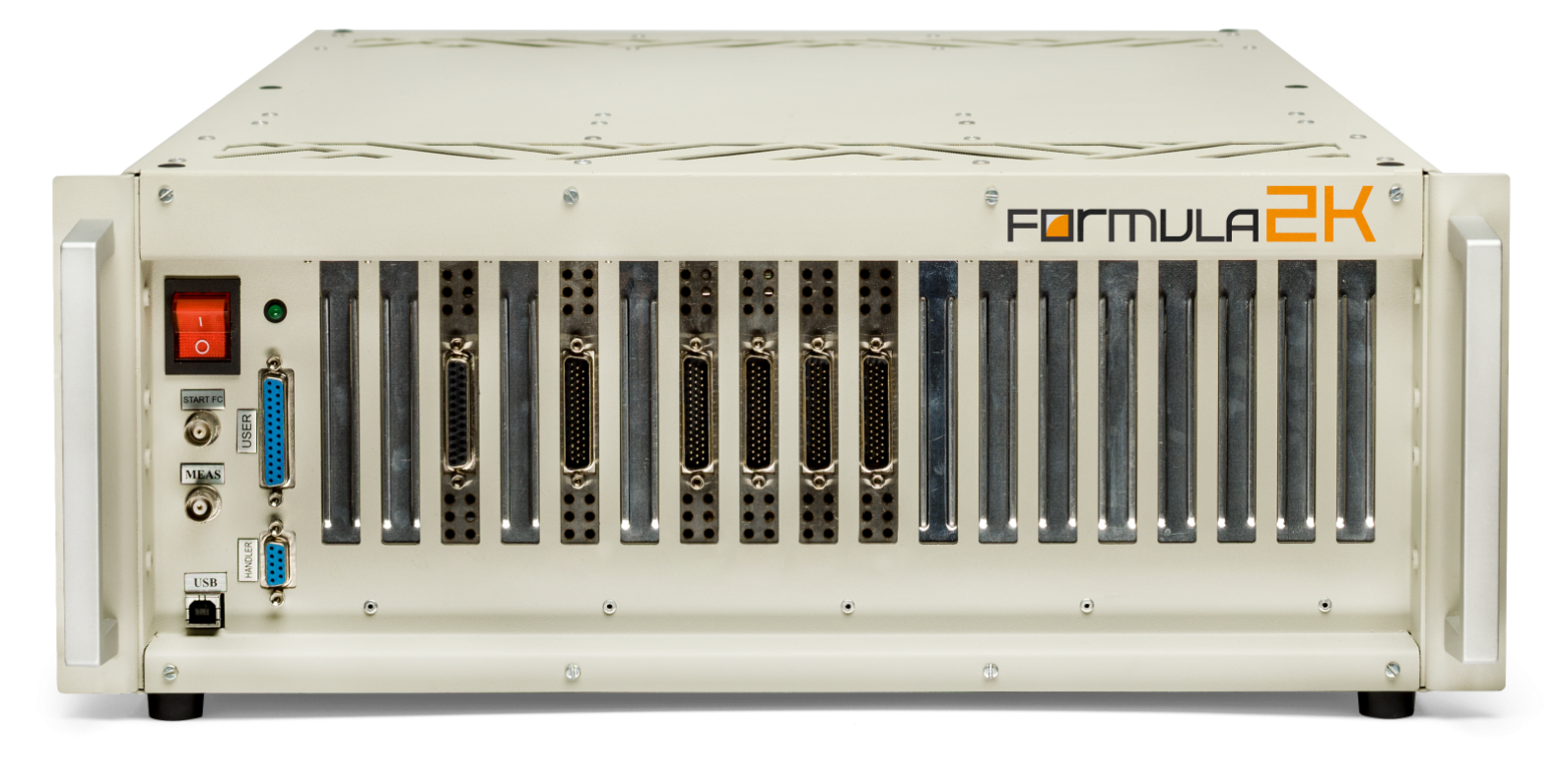

FORMULA® 2K test system

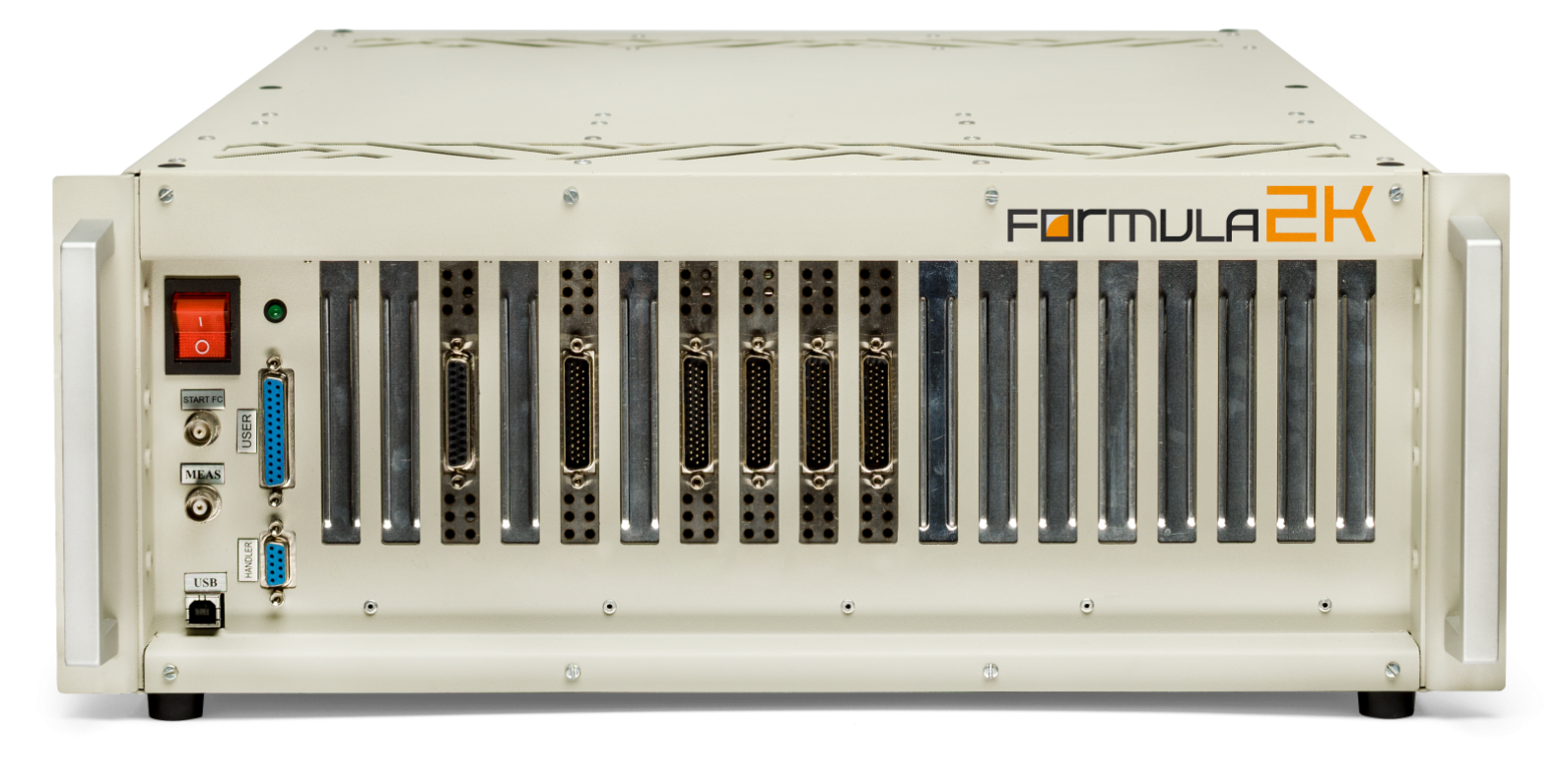

The FORMULA® 2K test system is a universal testing and measurement system designed for functional and parametric testing of small and medium-scale integrated digital and analog ICs, as well as memory chips.

The application of the Tester is quality control during incoming inspection, manufacturing and pre-shipment inspection, including certification testing.

Developer and Manufacturer of FORMULA® 2K Test Systems:

FORM, Russia

Basic technical characteristics and capabilities of FORMULA® 2К

The FORMULA® 2К Test System is a functionally complete automated apparatus for measurement of LSI and ICs and provides:

- High readiness of equipment for measurements and tests

- Automation of all stages of measurement process and data management

- Easily interchangeable test fixtures

- High-speed Multisite mode

- Easy integration with automated probes, loaders, test equipment and instruments

- User-friendly fully functional software

- Automatic diagnostics and metrological calibration

- Reliability in round-the-clock operation

Main advantages

The measurement process ideology implemented in FORMULA® 2K is essentially an integrated IC quality control business process driven by a system of rules and procedures set in Tester’s system software.

This applies to the development of test programs, and the order of access to changes in approved programs, and automatic documentation of all measurement results and parameters, including conducting metrological procedures, etc.

By purchasing FORMULA® 2K, the consumer gets everything one needs to perform measurements:

- Developer tools for measuring program in the SINOP graphic environment equipped with specialized proprietary compiler and library of high level functions

- Measuring program debugging tools, including an integrated logic analyzer, an oscilloscope, and a System Inspector, which allows one to check the status of any Test system device directly in the debugging phase

- Multifunction Test Processor for arbitrary logic chips, featuring a standard for IC-testers set of commands, including conditional transitions, nested loops, search for states, etc.

- Algorithmic test generator for memory and regular logic IC – an indispensable tool for proper testing memory ICs, without which the memory check is an overly laborious problem

- A single environment for controlling all stages of measurement process and maintenance

- Means of automatic statistics gathering, data collection and documentation of results

- Tools for automatic diagnostics and metrological procedures

- Differentiation of access levels for Users: software engineer/operator/metrologist/service engineer

- Ability to integrate with external instruments and devices, which is necessary for both the automation of metrological procedures and extending the functionality of a Test system - its use with probes, test equipment, additional instruments.

As a result, the FORMULA® 2K test system allows for creation of highly sophisticated workflows in the measurement process; ensures transparency, reliability and automation on all stages of IC testing. At the same time, the Test system is low-maintenance, designed for continuous operation, reliably retains all metrological characteristics between testings, needs no special infrastructure, can be moved easily, weight is less than 25 kg, and does not require a dedicated or purpose-built room.

All these qualities made FORMULA® 2K the most popular electronic components Test system of the last decade among Russian consumers.

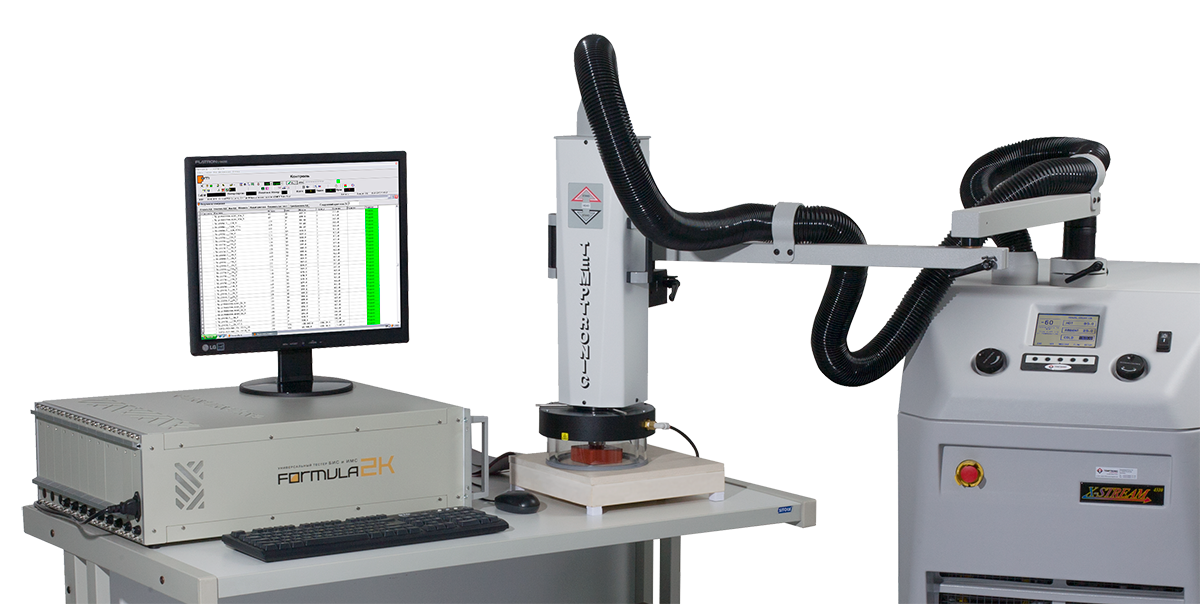

Using FORMULA® 2K for testing under environmental conditions

Тестер оснащен средствами для интеграции с внешним оборудованием отечественного и иностранного производства, в том числе, с зондовыми автоматами, испытательным оборудованием и измерительными приборами.

The ATE is equipped with means for integration with external equipment, including probes, test equipment and external instruments.

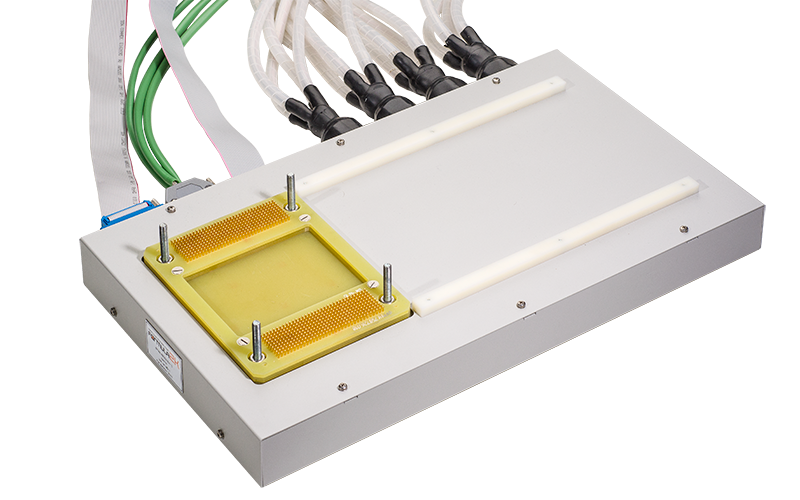

The original heat-resistant adapter specifically developed for FORMULA® 2K test system for testing ICs with up to 256 signal outputs allows for measurements under the influence of temperatures from –60 °C up to +125 °C with the use of «Thermostream». The use of heat-resistant contacts POGO-PIN in the adapter guarantees at least one million connections and disconnections.

SINOP software

The Test system software is based on the SINOP – Russian language graphics environment for Windows developed by FORM. The environment is user-friendly enough to allow an engineer who is not a programmer to learn it quickly and use it successfully.

Measuring accessory

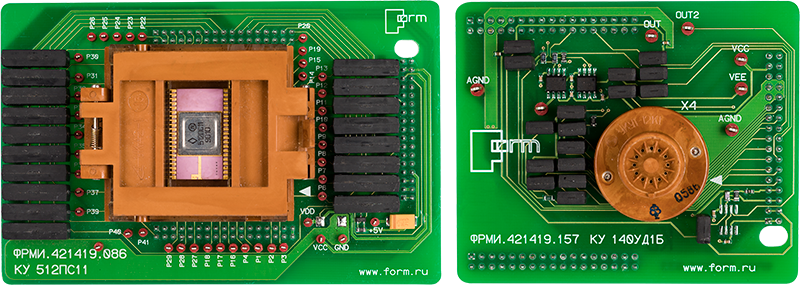

In FORMULA® 2K Delivery Specifications there is an optional test accessory suitable for a wide range of ICs. It is a universal adapter device – operator console used for testing and sorting components either on Pass/Fail basis or by validity.

Adapters are connected with a multi-wire planar or high-frequency cable. Also, they can be installed directly on the tester’s connectors. The adapter with 256 heat-resistant Pogo-Pin contacts is designed specifically for testing multi-leads ICs under the influence of extreme temperatures.

Universal adapters are used in conjunction with interchangeable equipment for different types of microcircuits. Upon Tester’s delivery, clients are provided with documentation on the independent development of measuring equipment.

Test solutions TestBox®

To let FORMULA® 2K owners get to real testing as soon as possible and promptly see a return on investment, FORM offers ready-made Test solutions as a boxed product.

We’ve been designing Test solutions for years and eventually created a whole library of solutions for a wide range of microcircuits. In package and on the wafer

- using autoloaders and probers

- under normal conditions and the influence of extreme temperatures: Termostream, pass-through chambers, heat-cold chambers

MANUFACTURER’S SERVICES

To reduce the Client’s time and costs for support work, FORM offers the following technical services:

- Integration of FORMULA® 2K Test Systems into the client’s technological, informational and testing infrastructure, with connection of external equipment, instruments and IT networks

- Organization of workstations based on FORMULA® 2K Test Systems with a database for ensuring traceability of measurements

- Maintenance, repair and metrological services

- Expansion of the ATE configuration according to a list of typical options, or with custom development of options

request a commercial offer

request a commercial offer