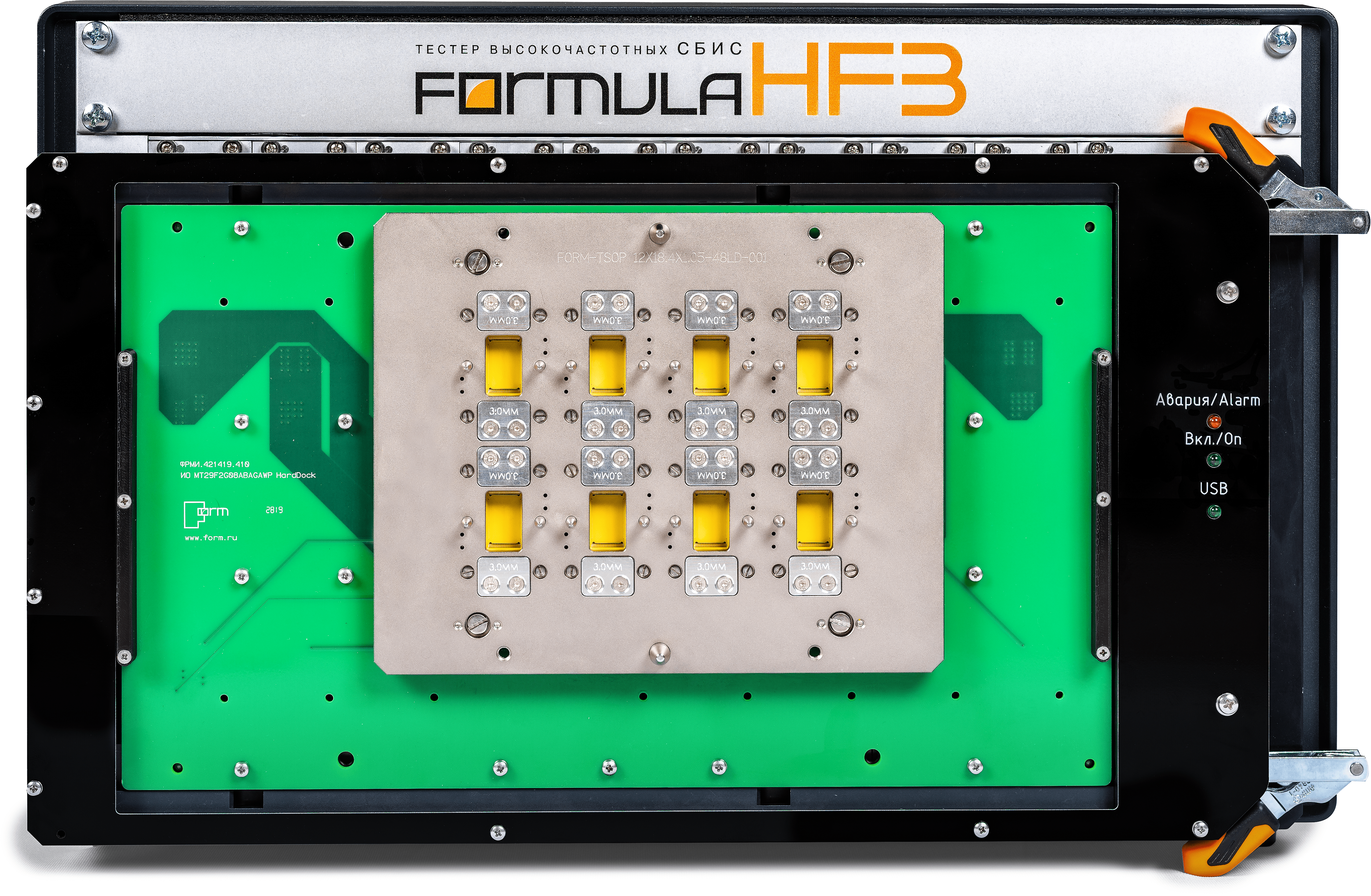

FORMULA® HF3 test system

Purpose and application

The FORMULA® HF3 Test System is an ATE for functional and parametric testing of ultrahigh-frequency VLSI circuits.

The applications for FORMULA® HF3 are:

- wafer sort and final test of serial VLSI circuits,

- studies of newly developed types of VLSI circuits,

- incoming inspection.

The FORMULA® HF3 meets the requirements of metrological standards in measurement and testing in microelectronics.

FORMULA® HF3 platform test systems come in two models – FORMULA® HF3 and FORMULA® HF3-512 – and are designed for functional testing of a wide range of high-speed VLSI circuits: logic; microcontrollers; memory; ASICs, FPGA and others with up to 256/512 signal outputs and operating frequency up to 200 MHz.

Basic technical characteristics and functional capabilities of FORMULA®

The FORMULA® HF3 Test System was created for reliable measurement and testing of a wide range of VLSI circuits.

The key technical characteristics of the test systems are defined by the following values:

The FORMULA® HF3 Test System is a functionally complete automated means of measurement for VLSI circuits and provides:

- Functional test frequency – up to 200 MHz per pin

- Number of universal bidirectional channels – up to 256/512

- Vector/error memory depth – up to 64 М/64 М vectors per pin; 1G vectors per board

- Overall Timing Accuracy (OTA) – not more than ±350 picosecond.

- High readiness of equipment for measurements and tests

- Automation of all stages of the measurement process and data management

- Operating modes with automated probes, handlers, test equipment and instruments

- High-speed Multisite mode

- User-friendly, fully functional software

- Quickly interchangeable loadboards

- Automatic diagnostics and metrological calibration

- Reliability in round-the-clock operations

FORMULA® has modular bus architecture that implements the principle of custom configuration of equipment with a choice of primary and secondary devices corresponding to the range of measurement and testing tasks.

The hardware, software, design and technological solutions realized in the systems provide characteristics and properties vital in making measurements, and in performing production tests and incoming inspection of VLSI circuits.

Use of the FORMULA® HF3 for testing under the environmental conditions

The design, hardware and software of the FORMULA® HF3 Test System create optimum conditions for testing microcircuits, including for testing combined with measurements, for example, using ThermoStream units and flow climatic chambers

An original new-generation DIB locker designed for measurements under both room temperature and in the range from –60 °C to +125 °C, was developed especially for the FORMULA® HF3 Test System.

Reliability, convenience, fast installation and replacement of loadboards are achieved by using a precision spring device, special frames and POGO-PIN contacts that guarantee at least a million loadboard connections.

Measurements under temperature effects directly on the spring base, without using cables, and without loss of signal quality are supported.

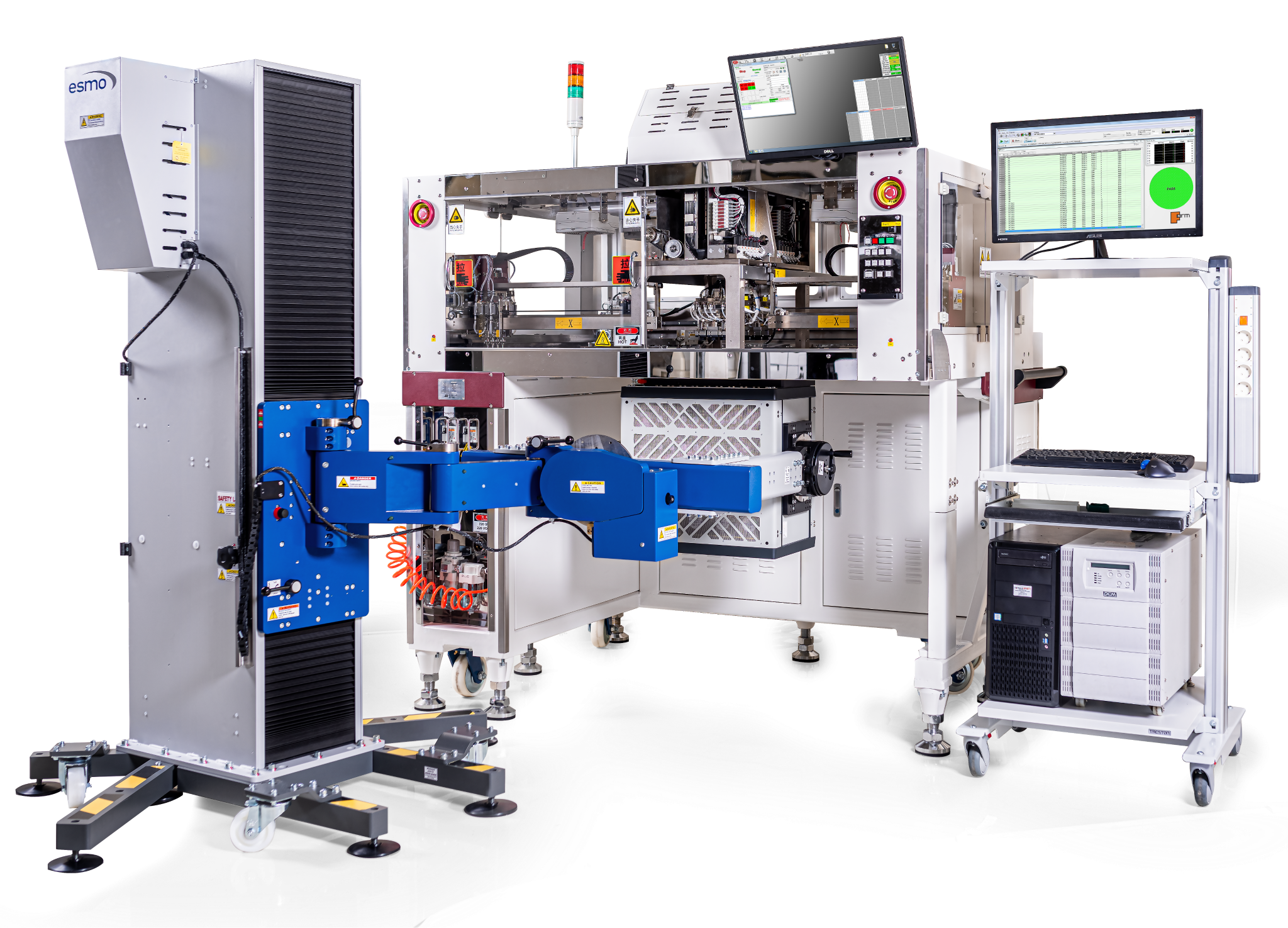

The manipulator makes it possible to rotate the FORMULA® HF3 test head in 3 axes for hard dock integration with probes and handlers.

FORMULA® HF3 software complex

The FORMULA® Test System software complex FormHF is the GUI-based environment designed for all stages of the measurement process.

The FormHF software complex is essentially a system for automation of the laborious process of development and debugging of test programs which has been adapted for use by a wide range of technical specialists without using programming languages. It supports all standard methods for testing microcircuits.

Graphic interpretation of measurements enables fast assessment of measurement results reduces the time for test development and debugging to a few days.

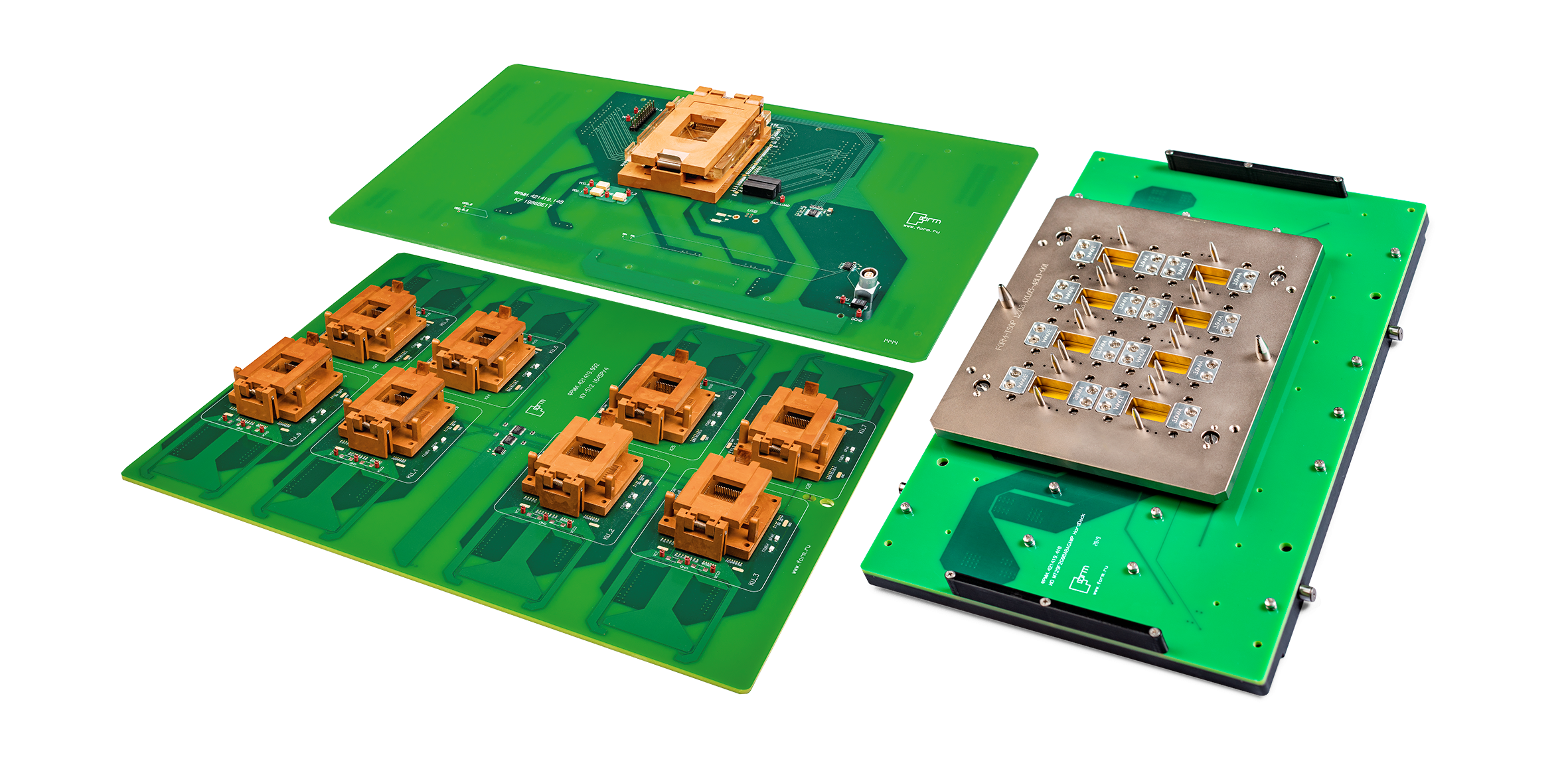

Loadboards. TestBox® Test Solutions

The FORMULA® delivery package includes standard installation frames for test boards and complete documentation for independent development of accessories by the Client.

So that FORMULA® HF3 Test System clients can more quickly achieve their business objectives and promptly see a return on investment, FORM custom TestBox® Test Solutions for measuring specific types of ICs:

- on a wafer or in a package

- in multisite mode

- in manual mode or automated mode with probers and handlers

- under room temperature and under the impact of extreme temperatures.

MANUFACTURER’S SERVICES

To reduce the Client’s time and costs for support work, FORM offers the following technical services:

- Integration of FORMULA® HF3 Test Systems into the client’s technological, informational and testing infrastructure, with connection of external equipment, instruments and IT networks

- Organization of workstations based on FORMULA® HF3 Test Systems with a database for ensuring traceability of measurements

- Maintenance, repair and metrological services

- Expansion of the ATE configuration according to a list of typical options, or with custom development of options