SINOP software

SINOP software

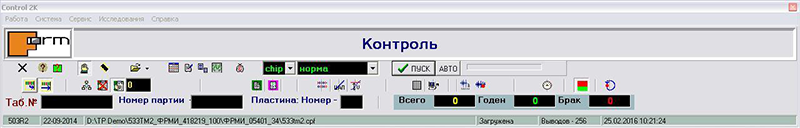

The Test system software is based on the SINOP -Russian-language graphics environment for Windows developed by FORM.

The environment is user-friendly enough to allow an engineer who is not a programmer to learn it quickly and use it successfully.

The SINOP software environment provides all the necessary tools for measuring: import test vectors in many different formats, debugging tools, means for collecting, storing and processing the results. All typical IC testing methods are supported.

Software environment SINOP provides flexible automation capabilities for measurement scripts development and debugging. This flexibility allows for easier operation by users of wide range of technical expertise.

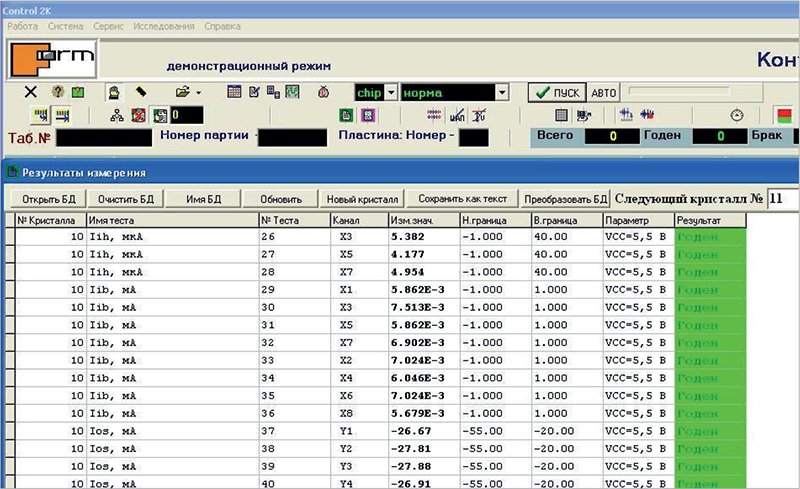

Results data storage and retrieval

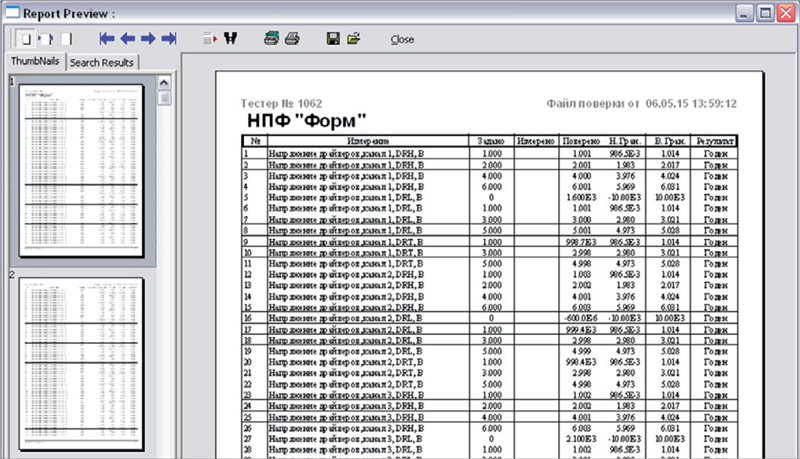

Automatic results data storage and report generation are necessary to determine compliance of a component under test with the requirements or technical specification. Test reports could vary in the level of detail: from mere “Pass” / “Fail” to complex reports for every component and parameter.

Results are stored automatically and can be easily converted into specific form used by Client. Subsequently they can be used as metrological basis for quality control management or for complaint claims in case of incoming inspection.

There is a possibility to create statistical reports for any given period sorted by batch, IC type, and other parameters.

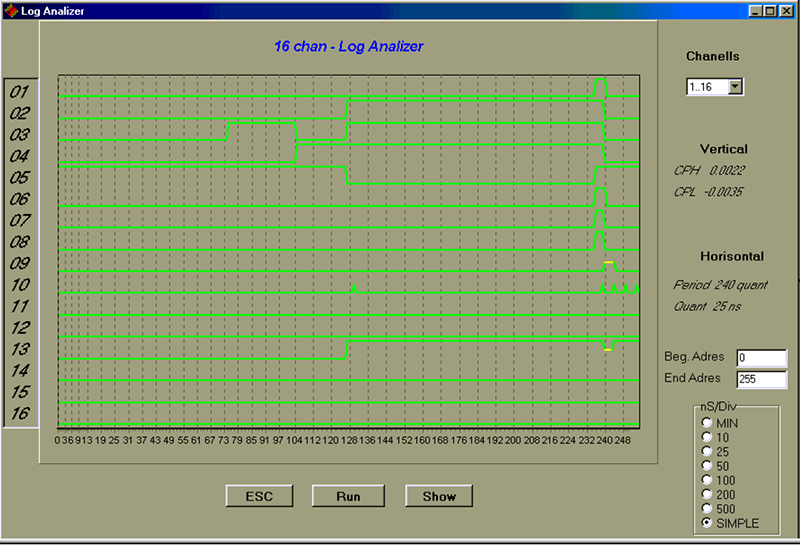

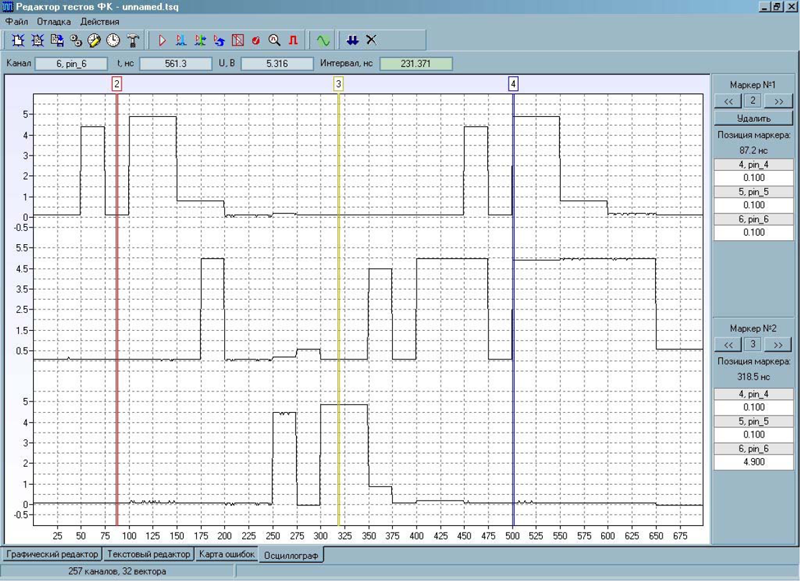

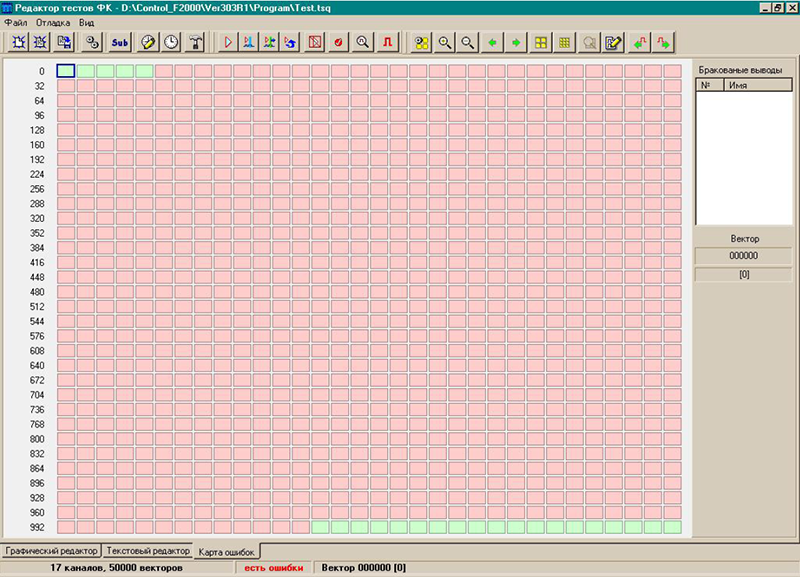

For the functional and parametric analysis of deviations detected in the measurement or debugging process built-in analytical tools are used. These include:

- hardware “Logical Analyser»

- «Oscilloscope»

- «Error Map»

which are particularly suitable for debugging of measuring routines and deviation analysis.

Service automation and metrological maintenance

Intelligent software environment SINOP automates not only measure-ment process, but Tester service and maintenance as well. It takes care of diagnostics, adjustment, metrological calibration and verification.

By automating Tester calibration and report generation, maintenance downtime can be reduced to a minimum and ensure result accuracy.

SINOP covers all bases of FORMULA® 2K operation, including performance monitoring, error detection and metrological compliance verification.